Combustible gas detector

With the progress and development of electronic science and technology, electronic technology has gradually become a powerful means of security, and many electronic products related to security are people's effective assistants in daily life.

A combustible gas detector is a detector that responds to the concentration of a single or multiple combustible gases. When a combustible gas in the environment leaks and reaches a certain concentration, the combustible gas detector will convert the on-site combustible gas concentration into an electrical signal, issue an alarm signal, and remind staff to take safety measures to achieve the purpose of monitoring the on-site combustible gas concentration.

During the design and construction process, combustible gas detectors should comply with corresponding standards and requirements, so this application requires extremely high ADC performance and MCU reliability.

Features of combustible gas detector scheme:

√ Main frequency up to 64MHZ, fast computation and processing speed;

√ S-485 interface/NB-iOT/4G CAT1;

√ Infrared remote control;

√ Audible and visual alarm;

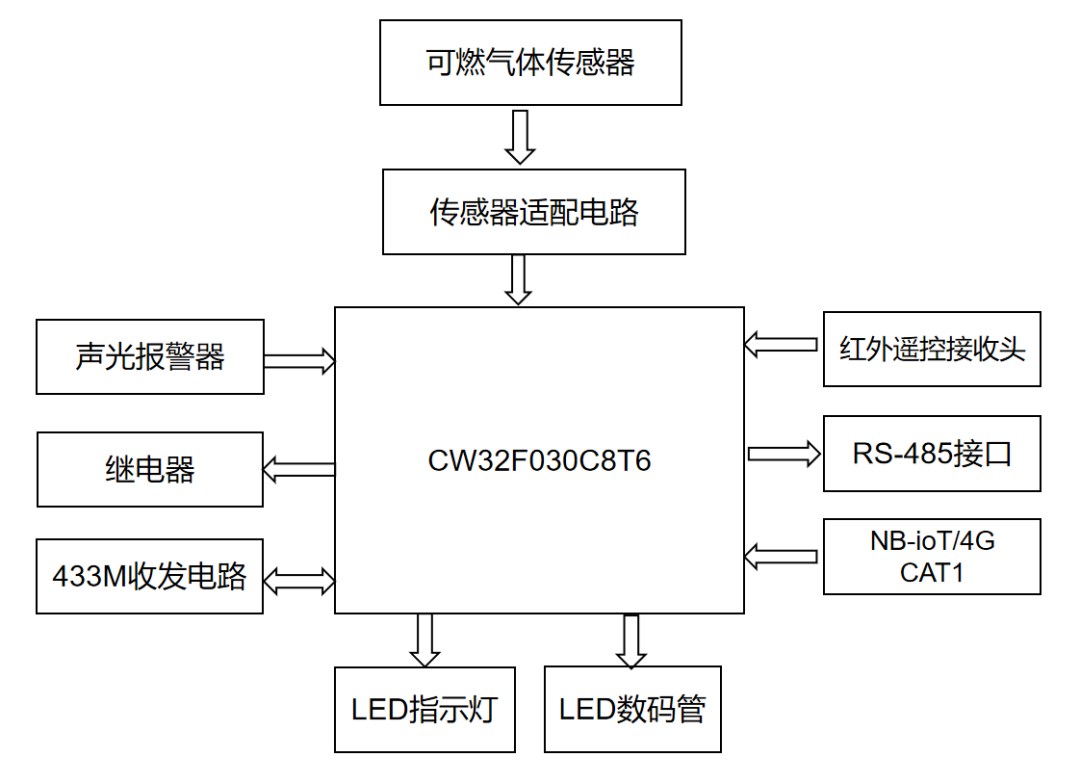

Application Block Diagram of Combustible Gas Detectors

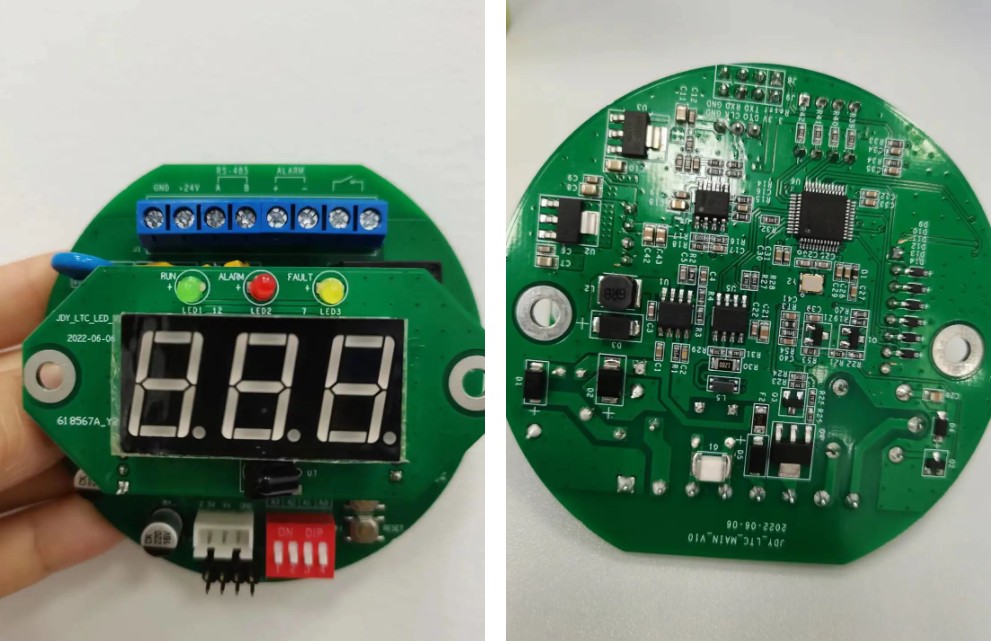

This combustible gas detector uses CW32F030C8T6 from Wuhan Core Source as the main control chip. It is mainly based on the high-precision ADC of CW32F030C8T6, with fast conversion speed, high reliability, strong anti-static, and strong anti-interference characteristics. It provides good protection functions for the system and ensures safe operation in harsh electromagnetic interference environments.

This combustible gas detector uses CW32F030C8T6 from Wuhan Core Source as the main control chip. It is mainly based on the high-precision ADC of CW32F030C8T6, with fast conversion speed, high reliability, strong anti-static, and strong anti-interference characteristics. It provides good protection functions for the system and ensures safe operation in harsh electromagnetic interference environments.

CW32F030C8T6 features and advantages:

√ ARM Cortex-M0+32-bit kernel;

√ 64K bytes of FLASH and 8K bytes of RAM;

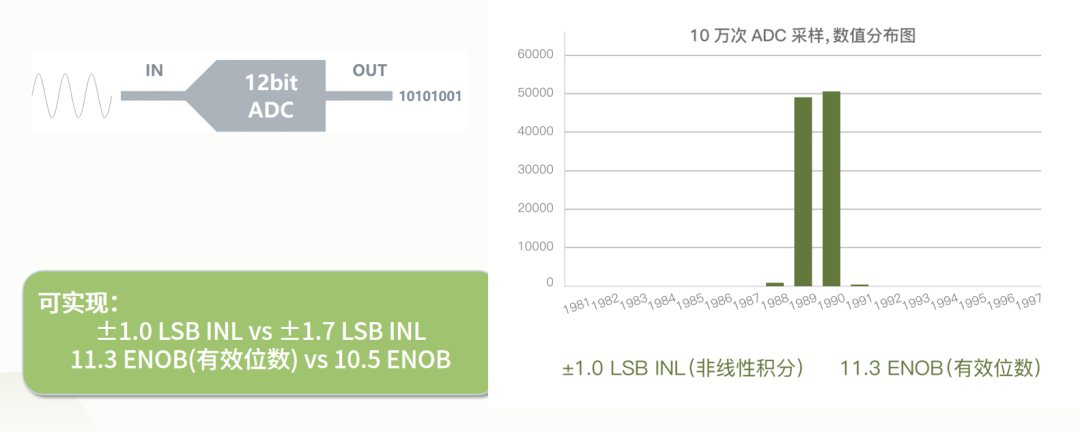

√ 12 bit ADC, 1M SPS conversion speed;

√ Three low-power UART, two SPI interfaces of 12Mbit/s, and two I2C interfaces of 1Mbit/s;

ADC performance assessment can achieve: ± 1.0 LSB INL vs ± 1.7 LSB INL, 11.3 ENOB (significant digits)

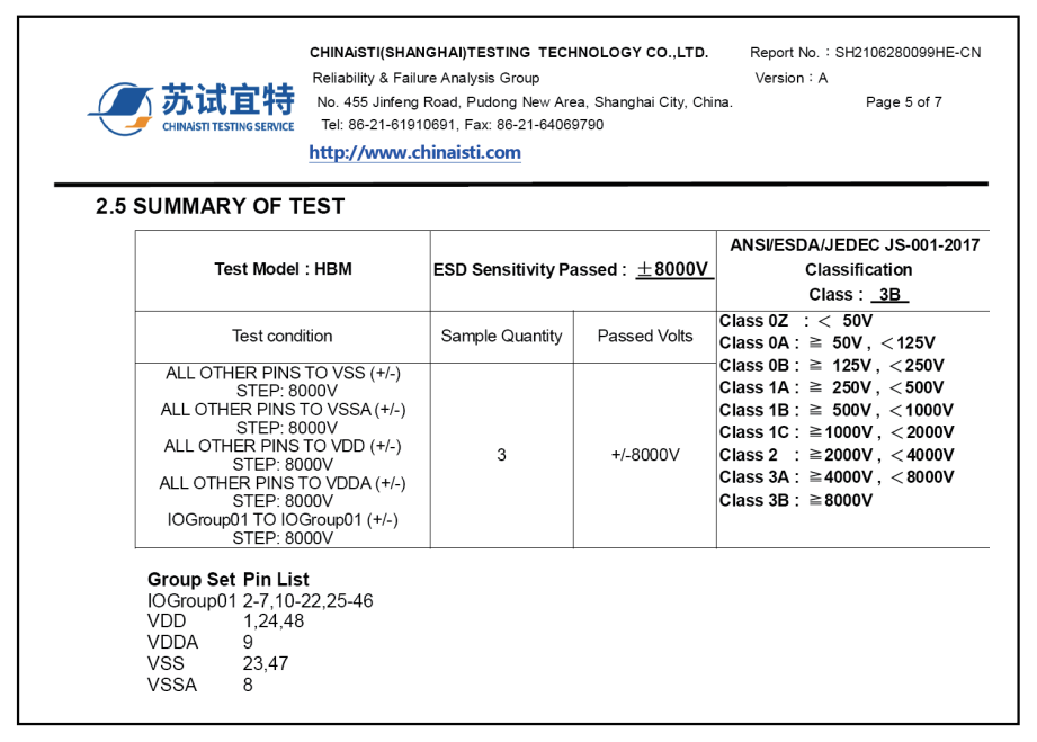

HBM ESD, MM ESD, CDM ESD, Latch up@105 Fully reaching the highest level of JEDEC at ℃

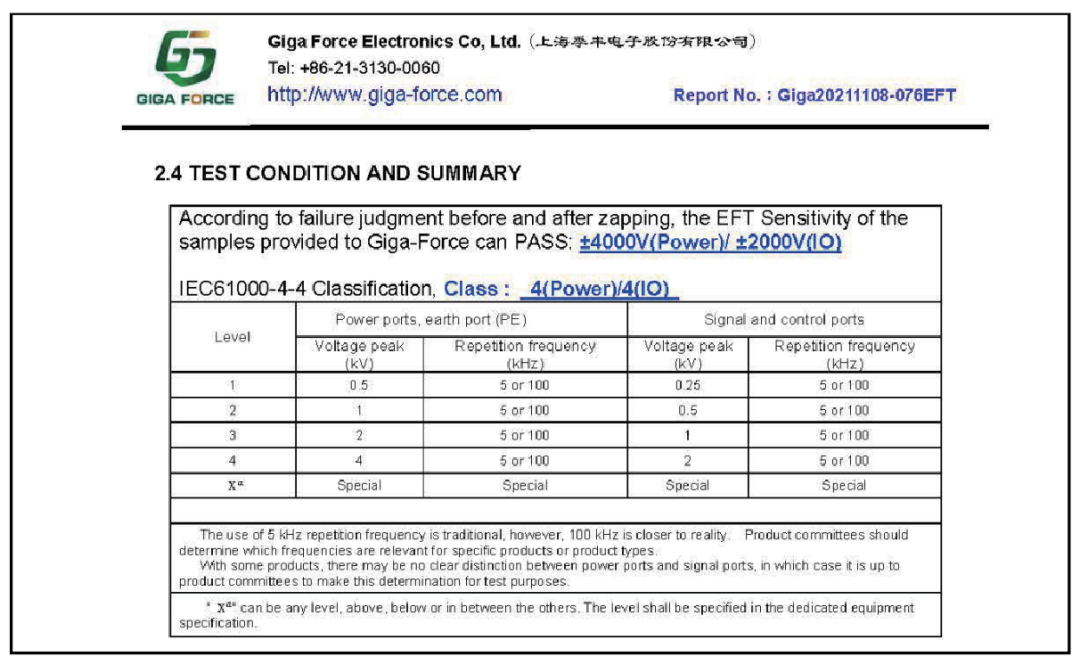

EFT test passed:±4000V(Power)/±2000V(IO)

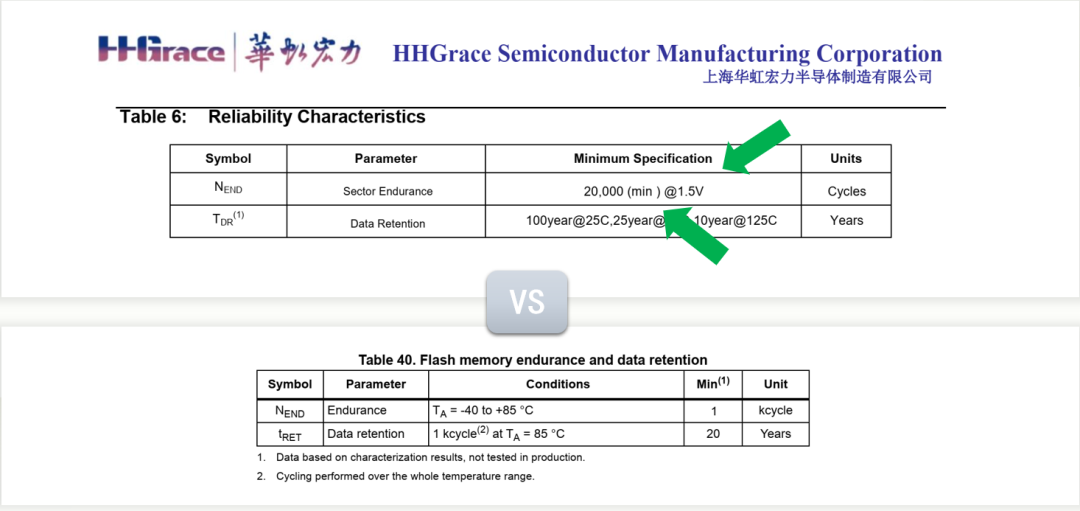

Stable and reliable eFLASH manufacturing ensures highly reliable industrial applications

-

Service hotline

全国咨询电话:

18002584030(WeChat)

商务合作:

Ms. Hu:13689515916(WeChat) janney@icchain.com

-

WeChat

-

Sample Application

鄂公网安备 42018502005668号 | 鄂ICP备2022001247号

鄂公网安备 42018502005668号 | 鄂ICP备2022001247号